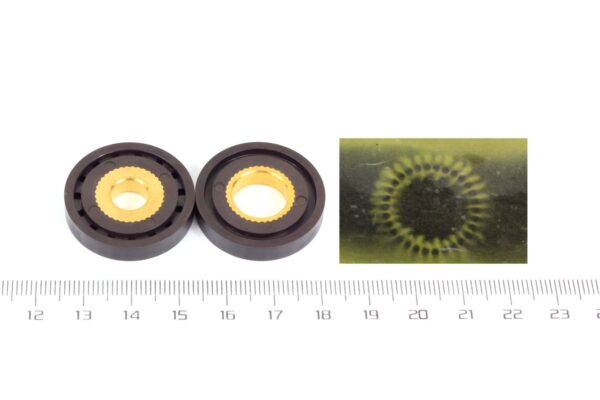

Description

The compound of injection molded ferrite is ferrite mixed with binder PA6, PA12 or PPS, binder selection depends on the application condition. Injection molded ferrite offers lower magnetic performance than that of injection molded neodymium. But injection molded ferrite is widely applied in industry.

Applications

Rotor, Motor, Automotive, Actuator, Compact Sensor, etc

Reviews

There are no reviews yet.